Background This paper presents the use of instrumented indentation as a mean to measure hardness and elastic properties of tablets, a technique proven to be more advantageous, reliable and precise than conventional techniques. Hardness and Young’s modulus are reported. Optically measuring the diagonals of indents is a well-established technique used to determine the hardness of bulk materials and coatings. Unfortunately, this technique is limited in its applications.At low loads, the indents can be so small that determining their size can involve unacceptable human errors. The texture and appearance of the surface can also complicate the observations, which is especially the case for tablets. Instrumented indentation is based on the analysis of the load-penetration curve measured while doing an imprint. It is computer-controlled and it is not influenced by the operator’s judgment of the imprint’s shape. Properties such as hardness, Young’s modulus, fracture toughness and creep behavior can be determined with a single indent. Load-penetration curves also reveal the load and depth at which cracking and failure occur. Samples The tablets are made of polymers, A and B, shaped in 1 centimeter diameter disks and have porosity (P) ranging from 3 to 8%. Measurements were performed in the center of the disks. Instrument The Micro Hardness Tester (MHT) from CSM Instruments was used with a Vickers diamond indenter. Values of hardness and Young’s modulus are computed using the Oliver and Pharr theory. Indentation is performed in less than 5 minutes including the time for tip approach. Testing Parameters Two sets of parameters are presented 1) Maximum load: 0.2N, loading rate: 0.4N/min, pause: 15s and 2) Maximum load: 1N, loading rate: 1N/min, pause: 15s. Results and Discussion Figure 1 shows a picture of a tablet after an indentation was performed with a maximum load of 1N.

Figure 1. Indent on a tablet with 1N load It reveals no apparent trace of imprint complicating the computation of hardness using conventional method in which case the diagonal is measured optically.

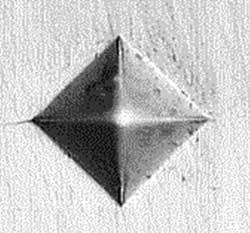

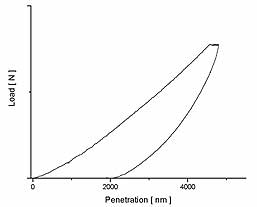

Figure 2. What indent should look like Thus using load-penetration curves (Fig. 3) from the instrumented indentation technique allows us to measure the level of hardness and Young’s modulus of various tablets with known porosity (Tables 1 and 2).

Figure 3. Example of indentation curve Table 1. Hardness (Hv, H), Youngs’ modulus (E) and penetration depth (ƒ´d) for maximum load of 0.2N | Tablet | P

[%] | Hv

[Vickers] | H

[MPa] | E

[GPa] | ƒ´d

[ ƒÝm ] | | A | 3 | 32 | 338 | 9.1 | 5.358 | | A | 4 | 29 | 305 | 8.1 | 5.625 | | A | 8 | 26 | 278 | 7.7 | 5.869 | | B | 3 | 13 | 136 | 3.1 | 8.575 | | B | 6 | 12 | 122 | 2.6 | 9.043 | | B | 8 | 7 | 74 | 1.7 | 11.634 | Table 2. Hardness (Hv, H), Youngs’ modulus (E) and penetration depth (ƒ´d) for maximum load of 1N | Tablet | P

[%] | Hv

[Vickers] | H

[MPa] | E

[GPa] | ƒ´d

[ ƒÝm ] | | A | 3 | 34 | 360 | 9.3 | 11.663 | | A | 4 | 23 | 246 | 3.4 | 15.044 | | A | 8 | 15 | 159 | 6.1 | 17.016 | | B | 3 | 13 | 141 | 3.1 | 18.886 | | B | 6 | 10 | 107 | 2.6 | 21.357 | | B | 8 | 3 | 34 | 0.4 | 42.331 | The sensitivity of the technique facilitates the monitoring of these properties even for small changes in porosity (1%) as well as in function of depth by using different indentation loads. Primary author: Ethel Poiré Source: EP Laboratories adapted from original poster presented at Biomaterials 2005 For more information on this source please visit EP Laboratories |

No comments:

Post a Comment