In a recent edition of Advanced Materials Magazine, the researchers demonstrate that controlling the structure of nanoparticles can "shrink" their visible size by a factor of thousands without affecting a particle's actual physical dimension.

"What we are doing is creating a novel technique to control the architecture of nanoparticles that will remedy many of the problems associated with the application of nanomaterials that are so essential to business sectors such as the aerospace and cosmetics industry," said Bockstaller, an assistant professor of materials science and engineering.

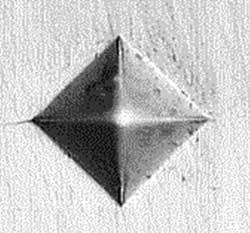

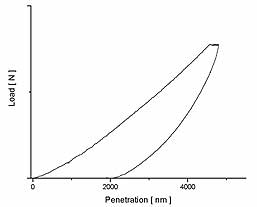

Colloidal particles are omnipresent as additives in current material technologies in order to enhance strength and wear resistance and other attributes. Light scattering that is associated with the presence of particles often results in an undesirable whitish, or milky, appearance of nanoparticles, which presents a tremendous challenge to current material technologies. Carnegie Mellon researchers have successfully created a way to prevent this problem by grafting polymers onto the particles' surface.

"Essentially, what we learned how to do was to control the density, composition and size of polymers attached to inorganic materials which in turn improves the optical transparency of polymer composites. In a sense, light can flow freely through the particle by putting 'grease' onto its surface," said Matyjaszewski, the J.C. Warner University Professor of Natural Sciences in the Department of Chemistry.

The new "particle invisibility cloak" will help create a vast array of new material technologies that combine unknown property combinations such as strength and durability with optical transparency.

Adapted from materials provided by Carnegie Mellon University.